How accurate is 3 sigma

Three Sigma is the third Sigma level, which dictates that there can only be a margin of error up to three standard deviations from the mean. This means that 99.7% of all outcomes fall within this range of accuracy. All Sigma levels measure the maximum number of allowable defects per one million parts.

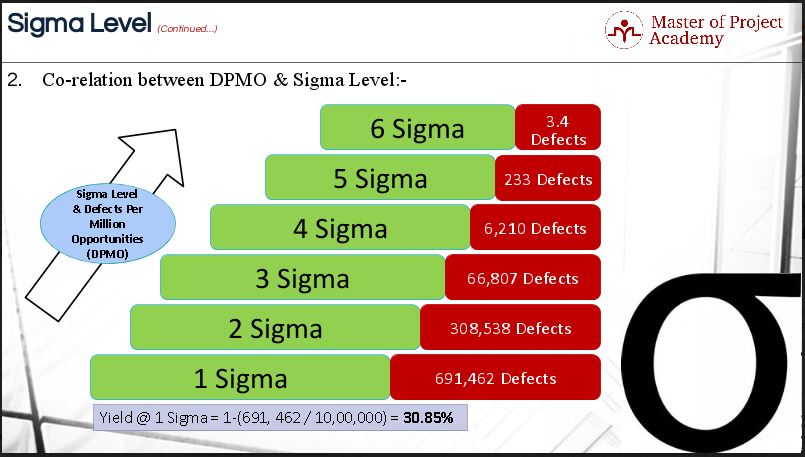

What is a good sigma level

6

A process with 50% defects (DPMO = 500,000) would have a Sigma Level of 0. Usually, a process with a Sigma Level of 6 or greater is usually considered as an excellent process.

Which is better 3 sigma or 6 sigma

3 sigma percentage is primarily used for manufacturing processes that allow for a 93.73% level of accuracy, and as a potential foundation for further process improvement. 6 sigma percentage is used for business activities that require the higher, 99.9997% positive outcome.

How many defects does 3 sigma mean

Sigma Performance Table

| Sigma Performance Levels – One to Six Sigma | ||

|---|---|---|

| Sigma Level | Defects (or Errors) Per Million Opportunities (DPMO) | Yield (or Produced or Delivered) Correctly (%) |

| 1 | 691,462 | 30.85 |

| 2 | 308,538 | 69.146 |

| 3 | 66,807 | 93.319 |

How rare is a 3-sigma event

In short, a 3-sigma detection event has a 0.3% probability of occurring by chance, and a 5-sigma event has just a 0.00006% probability of occurring by chance. Physicists traditionally call a 3-sigma detection "evidence", while a 5-sigma detection is considered a "discovery".

What does 3-sigma rating mean

Statistically speaking a 3-sigma rating means that 99.9% of the products are stronger than the reported MBS rating. What this means is a 3-sigma rated MBS is three standard deviations below the average breaking strength. Standard deviation helps to define the spread in the distribution of a given test sample.

What is the meaning of 3 sigma

What Is a Three-Sigma Limit Three-sigma limits is a statistical calculation where the data are within three standard deviations from a mean. In business applications, three-sigma refers to processes that operate efficiently and produce items of the highest quality.

What is a bad sigma level

For example, 1-sigma represents a poor level of quality, with 691,462 defects per million opportunities over time, which demonstrates a failure rate of over 69.1%. A level of 6-sigma represents a high level of quality, with 3.4 defects per million opportunities.

Why is 3-sigma important

In business applications, three-sigma refers to processes that operate efficiently and produce items of the highest quality. Three-sigma limits are used to set the upper and lower control limits in statistical quality control charts.

Is 2 sigma better than 6 Sigma

The more number of standard deviations between process average and acceptable process limits fits, the less likely that the process performs beyond the acceptable process limits, and it causes a defect. This is the reason why a 6σ (Six Sigma) process performs better than 1σ, 2σ, 3σ, 4σ, 5σ processes.

What is the result of 3-sigma

In the empirical sciences, the so-called three-sigma rule of thumb (or 3σ rule) expresses a conventional heuristic that nearly all values are taken to lie within three standard deviations of the mean, and thus it is empirically useful to treat 99.7% probability as near certainty.

How rare is 5 sigma

In most cases, a five-sigma result is considered the gold standard for significance, corresponding to about a one-in-a-million chance that the findings are just a result of random variations; six sigma translates to one chance in a half-billion that the result is a random fluke.

How rare is a 3 sigma event

In short, a 3-sigma detection event has a 0.3% probability of occurring by chance, and a 5-sigma event has just a 0.00006% probability of occurring by chance. Physicists traditionally call a 3-sigma detection "evidence", while a 5-sigma detection is considered a "discovery".

Is 6 Sigma +/- 3

The goal of a three sigma quality program is a deviation from an engineering specification of no more than one-sixth part — 1.66 percent, plus or minus. The goal of a Six Sigma quality program is a deviation of no more than one-twelfth part, or 0.83 percent, plus or minus.

What value is 3-sigma

99.7 percent

One standard deviation, or one sigma, plotted above or below the average value on that normal distribution curve, would define a region that includes 68 percent of all the data points. Two sigmas above or below would include about 95 percent of the data, and three sigmas would include 99.7 percent.

How to do 3-sigma

The three-sigma process:Carryout at least 5 breaks of the item to be rated.Calculate the mean.Calculate the standard deviation.Multiply the standard deviation by 3.Subtract the product in step 4 from the mean.

What is the meaning of 3-sigma

What Is a Three-Sigma Limit Three-sigma limits is a statistical calculation where the data are within three standard deviations from a mean. In business applications, three-sigma refers to processes that operate efficiently and produce items of the highest quality.

Why do we use 3 Sigma

In business applications, three-sigma refers to processes that operate efficiently and produce items of the highest quality. Three-sigma limits are used to set the upper and lower control limits in statistical quality control charts.

Is 1 sigma better than 2 sigma

One standard deviation, or one sigma, plotted above or below the average value on that normal distribution curve, would define a region that includes 68 percent of all the data points. Two sigmas above or below would include about 95 percent of the data, and three sigmas would include 99.7 percent.

What are the odds of 3 sigma

99.7%

Three sigma follows the 68-95-99.7 rule, where 68% of the data falls within one standard deviation of the mean, 95% of the data within two standard deviations of the mean and 99.7% of the data within three standard deviations of the mean.

What confidence is 3-sigma

99.7 percent

Two sigmas above or below would include about 95 percent of the data, and three sigmas would include 99.7 percent.

What does 3 sigma level mean

Three-sigma limits is a statistical calculation where the data are within three standard deviations from a mean. In business applications, three-sigma refers to processes that operate efficiently and produce items of the highest quality.

Which is better 1 sigma or 3-sigma

One standard deviation, or one sigma, plotted above or below the average value on that normal distribution curve, would define a region that includes 68 percent of all the data points. Two sigmas above or below would include about 95 percent of the data, and three sigmas would include 99.7 percent.

What is 3 vs 6 sigma

The Numerical Difference

The goal of a three sigma quality program is a deviation from an engineering specification of no more than one-sixth part — 1.66 percent, plus or minus. The goal of a Six Sigma quality program is a deviation of no more than one-twelfth part, or 0.83 percent, plus or minus.

Which is better 1 sigma or 3 sigma

One standard deviation, or one sigma, plotted above or below the average value on that normal distribution curve, would define a region that includes 68 percent of all the data points. Two sigmas above or below would include about 95 percent of the data, and three sigmas would include 99.7 percent.