Is 3 sigma better than 6 sigma

3 sigma percentage is primarily used for manufacturing processes that allow for a 93.73% level of accuracy, and as a potential foundation for further process improvement. 6 sigma percentage is used for business activities that require the higher, 99.9997% positive outcome.

What is the difference between 6 and 3 sigma

The Numerical Difference

The goal of a three sigma quality program is a deviation from an engineering specification of no more than one-sixth part — 1.66 percent, plus or minus. The goal of a Six Sigma quality program is a deviation of no more than one-twelfth part, or 0.83 percent, plus or minus.

Is 2 sigma better than 6 sigma

The more number of standard deviations between process average and acceptable process limits fits, the less likely that the process performs beyond the acceptable process limits, and it causes a defect. This is the reason why a 6σ (Six Sigma) process performs better than 1σ, 2σ, 3σ, 4σ, 5σ processes.

Why 6 sigma is better

Six Sigma is a method that provides organizations tools to improve the capability of their business processes. This increase in performance and decrease in process variation helps lead to defect reduction and improvement in profits, employee morale, and quality of products or services.

Is 3 sigma good enough

Sigma Level 3 is considered a good level of performance for most processes and products. This means that 99.73% of the process output meets customer expectations, which is impressive. For many businesses, having this level of quality assurance can significantly improve their operations and customer satisfaction.

How rare is a 3 sigma event

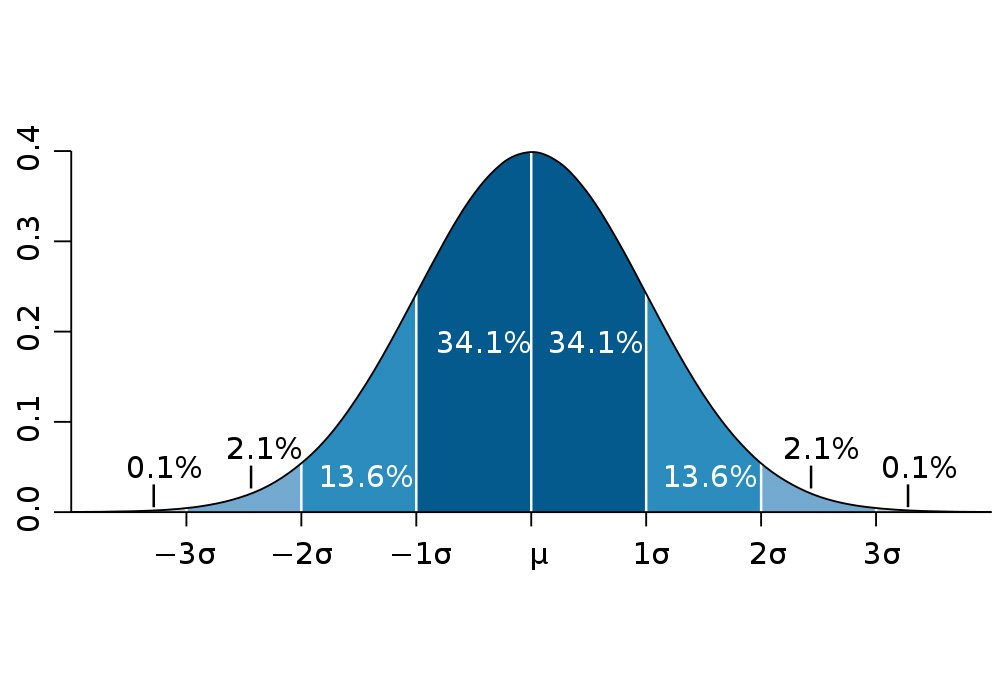

In short, a 3-sigma detection event has a 0.3% probability of occurring by chance, and a 5-sigma event has just a 0.00006% probability of occurring by chance. Physicists traditionally call a 3-sigma detection "evidence", while a 5-sigma detection is considered a "discovery".

Is 3-sigma good enough

Sigma Level 3 is considered a good level of performance for most processes and products. This means that 99.73% of the process output meets customer expectations, which is impressive. For many businesses, having this level of quality assurance can significantly improve their operations and customer satisfaction.

Why not use Six Sigma

It's too complex.

Another reason many companies don't adopt Six Sigma is because it seems like an overwhelming task. Many people think they need to hire consultants, buy expensive software or train employees before implementing any improvements.

How accurate is 3 sigma

Three Sigma is the third Sigma level, which dictates that there can only be a margin of error up to three standard deviations from the mean. This means that 99.7% of all outcomes fall within this range of accuracy. All Sigma levels measure the maximum number of allowable defects per one million parts.

Is 5 sigma better than 6 Sigma

The higher the sigma level the better the quality of the product or service and the fewer the defects. Organizations with a Six Sigma quality have an advantage over others who perform at three, four or even five sigma levels.

What is the disadvantage of 6 Sigma

Six Sigma Disadvantages

In addition, its customer focus may be taken to extremes, where internal quality-control measures that make sense for a company are not taken because of the overlying goal of achieving the Six Sigma-stipulated level of consumer satisfaction.

How rare is a 3-sigma event

In short, a 3-sigma detection event has a 0.3% probability of occurring by chance, and a 5-sigma event has just a 0.00006% probability of occurring by chance. Physicists traditionally call a 3-sigma detection "evidence", while a 5-sigma detection is considered a "discovery".

Is Six Sigma really worth it

Learning Six Sigma methodologies for your work life can help impact your career future. The ability to add Six Sigma Certification to your resume proves your commitment to improving your business acumen and analytical skills, as well as improving the business where you work.

How rare is 5 sigma

In most cases, a five-sigma result is considered the gold standard for significance, corresponding to about a one-in-a-million chance that the findings are just a result of random variations; six sigma translates to one chance in a half-billion that the result is a random fluke.

What is a 7 sigma event

• a 7-sigma event is to be expected every 7.76e+11 days – the number of zero. digits is so large that Excel now reports the number of days using scientific. notation, and this number is to be interpreted as 7.76 days with decimal point.

Why Six Sigma is not successful in all companies

Outside of a manufacturing operation, Six Sigma often fails to yield the kind of results needed to justify such a time-consuming and expensive management change. To function effectively, Six Sigma requires buy-in from everyone involved.

How accurate is Six Sigma process

Six Sigma (6σ) is a set of techniques and tools for process improvement. A six sigma process is a statistical tool in which 99.99966% perfection is achieved. It was introduced by engineer Bill Smith while working at Motorola in 1980.

Is Six Sigma outdated

Still, despite a lower profile, the process remains relevant. For those who have forgotten, or simply weren't around a decade or so ago when it was the focus of numerous books, articles, and panel discussions, Six Sigma is a process that relies on statistics and data analysis to reduce errors or defects.

Why did Six Sigma fail

Lack of management support

Management lacks the commitment to provide the resources. Six Sigma projects require people from different departments to come join, do data analyses and if these people are not freed or spared from that department, you really cannot do anything. The project is bound to fail.

What is a 10 sigma event

A 10-Sigma would be an event that happens once every 5.249e+020 years (that's half a Septillion). A 10-Sigma is more like a metaphor for something that can never happen or is so great of a number you might as well use infinity.

What is a 12 sigma event

High Sigma events could be said to have the odds of occurring roughly once in thousands of years. For example, an event over 12 Sigma has the odds of occurring only twice in 10,000 years.

Why did Six Sigma project fail

Failure means inability to achieve the objective which Six Sigma projects were supposed to achieve. Following are some of the reasons for a Six Sigma project to fail. The top reason is the lack of management support. Management lacks the commitment to provide the resources.

What companies failed with Six Sigma

Examples like Home Depot and 3M show that companies cannot focus on implementing Six Sigma in isolation. Clearly, Six Sigma is a set of process tools that should only be part of a more holistic process improvement strategy.

How unlikely is 5 sigma

In most cases, a five-sigma result is considered the gold standard for significance, corresponding to about a one-in-a-million chance that the findings are just a result of random variations; six sigma translates to one chance in a half-billion that the result is a random fluke.

Is Lean Six Sigma dying

So while Lean Six Sigma as a brand is dead, as a mindset, it's as alive as ever. And that's probably a good thing too. Finally, there is a greater need for what can be called operational excellence thinking (including lean and six sigma methods) than ever before.