Why did 3D printing fail

There are many reasons why a 3D print might fail. It could be due to mechanical issues that cause uneven movements, which could then knock over a model, down to software issues with settings that are too high, like the temperature. Even having a fluctuating room temperature could result in a failed 3D print.

What is the problem with 3D printing

Some common hazards include: Breathing in harmful materials: 3D printing can release particulates and other harmful chemicals into the air. Skin contact with harmful materials: Users can get hazardous materials, such as metal powders, solvents and other chemicals, on their skin.

What are the biggest problems in 3D printing

Critical 3D Printing Problems and Solutions

Today, however, challenges seem to vary: the cost of pre- and post-processing, the limited selection of materials and technology limitations are the biggest 3D printing challenges of 2021.

Why is 3D printing weak

If the print head isn't hot enough, filament won't melt consistently, which can lead to under-extrusion and weak bonding between layers. A higher temperature will cause the filament to melt faster and result in a stronger filament flow through the nozzle.

Why is 3D printing not sustainable

While production times may be condensed, the amount of energy required to create a product is still high. That's because 3D printing builds parts very slowly. “So, in general, we must invest a lot of energy in the manufacturing process over a relatively long period of time,” explains Bourell.

Why aren t 3D printers more popular

But the software is complex, the machines are sensitive and require constant calibrating, the cheap models are small, and printing even the simplest design can take hours. “3D printing will remain a niche product for the foreseeable future,” Jager said.

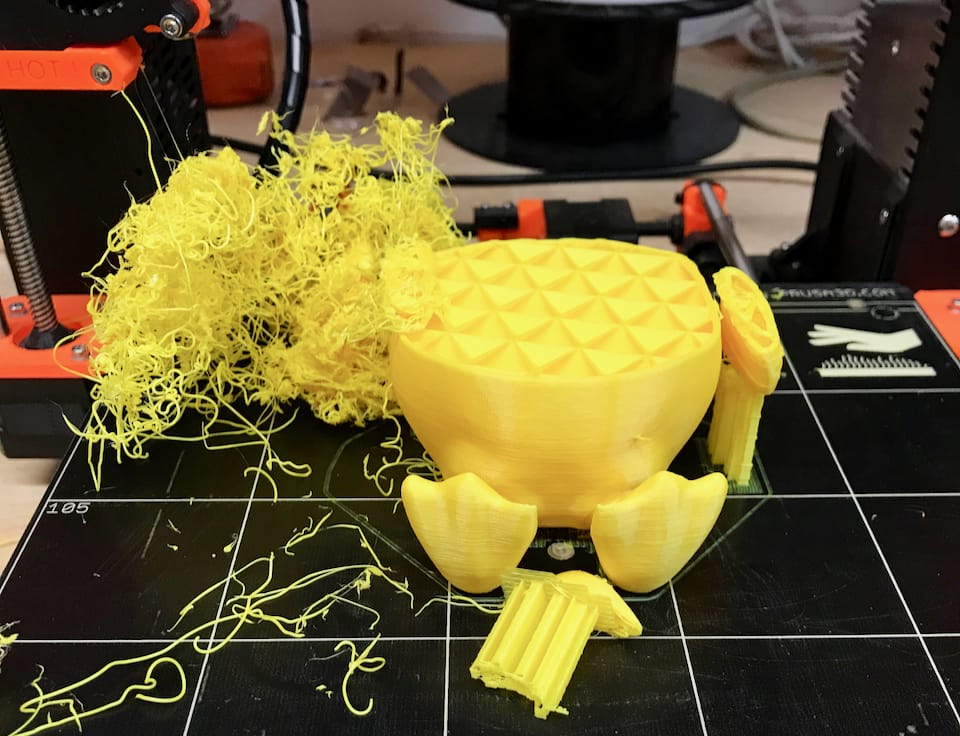

What is the most common 3D print failure

The 3 most common 3D print failures are under/over-extrusion, oozing, and calibration error.

What are two problems associated with 3D printing

Equipment and product costs are high.

Even when manufacturers have access to this equipment, the process moves very slowly. Unlike traditional manufacturing, there are high costs associated with producing large volumes of certain products using 3D printing.

What is the disadvantages of 3D printing

Labor costs

Unlike traditional manufacturing where different people may be required to operate a number of different machines or a production line is required to put the product together. Each 3D printer will require an operator to start the machine and start the automated process of creating the uploaded design.

Why is PLA so weak

Unfortunately, its low melting point also causes it to lose virtually all stiffness and strength at temperatures above 50 degrees Celsius. In addition, PLA is brittle, leading to parts with poor durability and impact resistance.

Is 3D printing good or bad for the environment

3D printing reduces the environmental impact of manufacturing by lowering waste, energy usage, and need for space compared to traditional factory processes. The short answer is yes — one key way manufacturers can have a less harmful impact on the environment is by additively manufacturing whatever components they can.

Does 3D printing result in waste

Despite the numerous advantages of 3D printing, the process itself generates large amounts of waste. As a provider of sustainable materials for 3D printing, Filamentive is regularly asked by customers, researchers and industry professionals about the true scale of plastic waste generated by 3D printing.

Does 3D printing have a future

The development of new software has made 3D printing more accessible and user-friendly, allowing for easier design and preparation of parts for printing. Overall, the vision for materials in 3D printing in 2023 is one of increased diversity, performance, and sustainability.

What is stopping 3D printing from being used now

In addition to price, the complexity of most 3D printers is holding them back. Pete Basiliere, an analyst at Gartner, notes that 3D printers are more complex than paper printers, and haven't been able to deliver on ease of use.

Is 3D printing inefficient

While other methods of construction can take minutes to make a piece, the layer-by-layer method the 3d printers use makes them inherently slower due to the physical limitations inherent to the technology, both for Fused Deposition Modeling (FDM) and for Resin-Based printers.

How bad is 3D printing for the environment

The technology uses larger amounts of energy than milling and drilling machines. And to produce an object of the same weight, the 3D printing process may require 50 to 100 times more electrical energy than standard machines, thereby causing more emissions.

What are the pros and cons of 3D printing

Pros: allows you to make new shapes, it's eco-friendly and it saves time. Cons: doesn't always work well for large projects, appropriate materials aren't always available and it has regulatory challenges.

Why is PLA not widely used

The biggest problem with PLA is the very specific conditions needed in order for it to be properly composted. Instead of being recycled with regular plastic materials, PLA needs to be sorted separately and brought to a 'closed composting environment' as otherwise it contaminates the recycling stream.

Why is PLA not used more

PLA has a higher permeability than other plastics. Moisture and oxygen will go through it more easily than other plastics. This will result in faster food spoilage. PLA is not recommended for long-term food storage applications.

Why is 3D printing bad for the environment

Many 3D-printing materials are plastic

“You therefore have an unfortunate choice between slower 3D-printing processes that use recyclable thermoplastic materials and faster 3D-printing processes that require disposal of hazardous waste.” Plus, a lot of the plastic will still wind up in landfills someday.

Is 3D printing still a trend

3D printing growth indicators

In this year's trend report, based on Hubs' internal data and the average CAGR forecasts from 10 leading market analysis firms, the 3D printing market is set to experience a 17% growth, reaching a value of $19.9 billion by 2023.

Will 3D printing replace manufacturing

So, will 3D Printing Replace Traditional Manufacturing Well, considering the comparison we have done above, it would take decades for 3D printing to replace traditional manufacturing. In the near future; however, we can say that 3D printing could modify or improve some processes in the industry.

Why is 3D printing unethical

Thus, 3D printing can become a potential danger when serving the needs of criminals or counterfeiters. 3D printing in the aspect of terrorism or other acts of violence against social norms present real threat. Moreover, major ethical issue is the use of materials for 3D printing, or in this case, bio-printing.

What are disadvantages of 3D graphics

Cons of 3D motion graphics

One of the main drawbacks of 3D motion graphics is that they are more difficult and time-consuming to create and edit. You need to have advanced skills and knowledge in 3D modeling, animation, rendering, and compositing to make your 3D animations look good and work well.

Is PLA actually eco friendly

Lower Carbon Footprint

The manufacturing process for PLA is also more environmentally friendly than traditional plastics. Ingeo PLA bioplastic produces 80% less greenhouse gas emissions compared to conventional plastic derived from fossil resources (source).