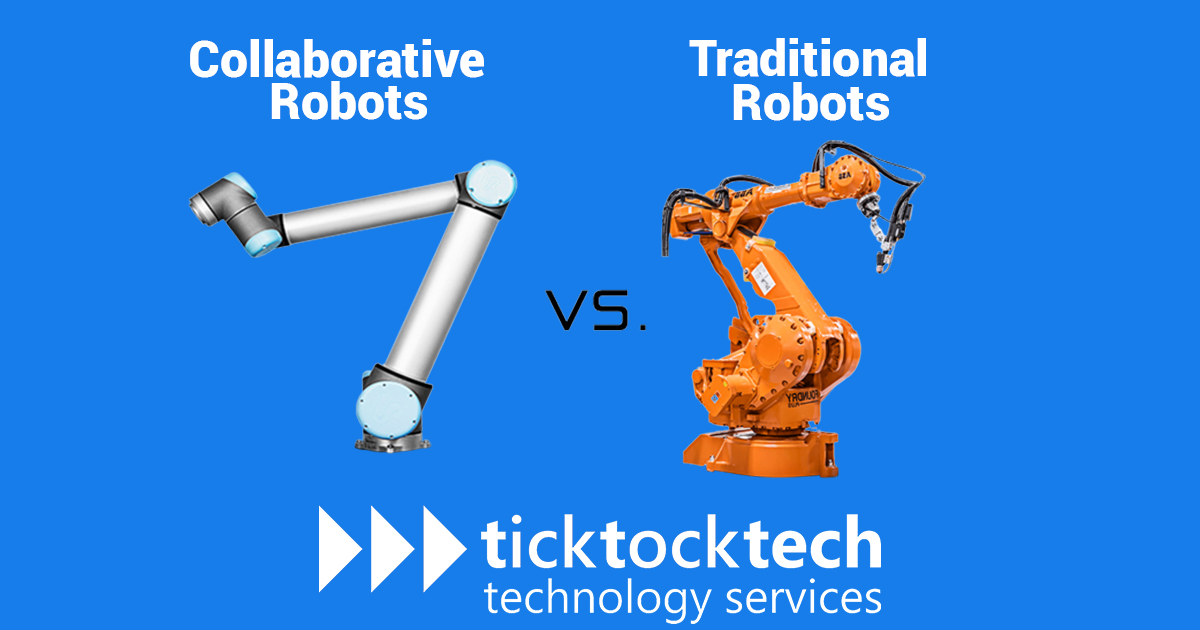

How are cobots better than robots

Cobots provide less risk to human safety than traditional robots and are better suited for environments that require adaptability. They offer flexibility for fluctuating work environments that traditional robots can't match.

How are the cobots different from robots

Functionality: Unlike traditional robots, cobots can easily be moved and utilized in different areas of production. Most can be mounted on any surface – horizontal, vertical, on the ceiling. They are often light enough to be carried by just one person, which is not usually the case with traditional industrial robots.

What are cobots good for

A cobot is designed to work with people and not to replace people. Cobots are also called people-focused robots and can help people to make and refine the work they do easier. Dirty, unsafe, boring, monotonous or repetitive tasks can be performed by the robot so that employees can concentrate on other tasks.

What is the difference between cobot and industrial robot

Key Differences Between Cobots and Industrial Robots

The simplest way to understand how cobots and industrial robots differ is that cobots are designed to work alongside human employees, while industrial robots do work in place of those employees.

Are cobots cheaper than robots

Conventional robots can be incredibly powerful and efficient machines, capable of executing the same complex production tasks repeatedly for months on end. But they do take a long time to deploy and are expensive. Cobots, on the other hand, are lighter and more affordable than conventional robots.

What is better for robotics

Mechanical engineering is one of the best college majors for students interested in robotics. It's a highly interdisciplinary field that combines principles of mechanics, electronics, and control systems. Mechanical engineers use their skills to design, build, and test mechanical devices, including robots.

What is a cobot not robot

A cobot, or collaborative robot, is a robot intended for direct human-robot interaction within a shared space, or where humans and robots are in close proximity. Cobot applications contrast with traditional industrial robot applications in which robots are isolated from human contact.

Are cobots the future

Powering the future of smart manufacturing

By leveraging the combined power of humans and machines, cobots will play a huge role in smart factories and will lead to significant improvements in quality and productivity levels.

What is the difference between industrial and collaborative robots

Remember that the key difference between industrial robots and collaborative robots is that industrial robots can entirely automate a process without human interaction, while COBOTs work with humans. COBOTs also cannot take on some of the heavy-duty manufacturing jobs that should be performed by an industrial robot.

Do cobots work with humans

Cobots, or collaborative robots, are robots that work safely alongside humans. They are often designed to take on menial, repetitive tasks, freeing up humans to focus on more important, and enjoyable, aspects of their jobs.

Which is better robotics or automation

Let's imagine we need to speed up our production operations and need to assemble a product faster. A robot might be able to help. Software-driven process automation would be more suited if we wanted to make repetitious administrative activities more efficient.

What are the biggest problem in robotics

Data privacy and security are some of the most important issues that are currently prevailing in the industry. Robots too need several private data and process sensitive information in order to accomplish their tasks.

Is cobot a robot

A collaborative robot, also known as a cobot, is an industrial robot that can safely operate alongside humans in a shared workspace. In contrast, autonomous robots are hard-coded to repeatedly perform one task, work independently and remain stationary.

What problems do cobots have

Cobots are not suitable for high-speed and high-payload tasks. Compared to traditional industrial robots, cobots typically operate at slower speeds, averaging around 250mm, which can impact overall work pace.

How are cobots different from their predecessors

Cobots are more intelligent than their predecessors. They are designed to work safely alongside humans. They can respond to human movement in a split second by reducing their speed and preventing injury.

Who is the most human like robot

AMECA (ENGINEERED ARTS)

Ameca is the world's most advanced, most realistic humanoid robot created by Engineered Arts in 2021.

Which is best for robotics

Many aspiring robotics engineers tend to pursue a mechanical or electrical engineering degree with a focus on robotics. You can choose from various majors and still have access to a robotics career, including: Electrical/electronics engineering. Mechanical engineering.

What are 3 disadvantages of robots in industry

To address both sides of the discussion, we have put together a few brief advantages and disadvantages of using robotic automation.ADVANTAGES.Cost Effectiveness.Improved Quality Assurance.Increased Productivity.Work In Hazardous Environments.DISADVANTAGES.Potential Job Losses.Initial Investment Costs.

What are the weaknesses of robotics

Often robots are very costly – in terms of the initial cost, maintenance, the need for extra components and the need to be programmed to do the task.

Is Siri a human or a robot

Siri's features power from narrow AI. The capabilities are limited to performing tasks such as setting reminders or managing phones. Siri cannot be an advanced robot or a humanoid replacement.

Is Sophia the robot a human

Sophia is one of the most sophisticated artificial intelligence (AI) humanoid robots able to interact with people and demonstrate humanlike expressions.

Which is better AI or robotics

The difference that makes the AI stand out is the ability to make decisions. It can make the software yield better results, i.e., improvisation. AI is a technological brain with wires and programming. Robots need prior instructions or codes of instruction to perform autonomously or semi-autonomously.

What are the limitations of Cobots

Cobot speed is limited

When users interact with the cobot, its speed is reduced to embrace safety – at the expense of cycle time. Therefore, applications which demand high speed are typically not recommended for cobots.

What is the negative impact of robotics

Robots can create economic problems because they continuously replace humans. Robots can only do what they are told to do, meaning they can't do more than expected without any command (by the way, machine learning and Artificial Intelligence are working on it).

Is Siri real name

Even if you're not familiar with the name Susan Bennett, you'd likely recognize her voice. As the original Siri, Bennett became a dependable presence in many iPhone users' lives, responding to various inquiries and fulfilling spoken commands.